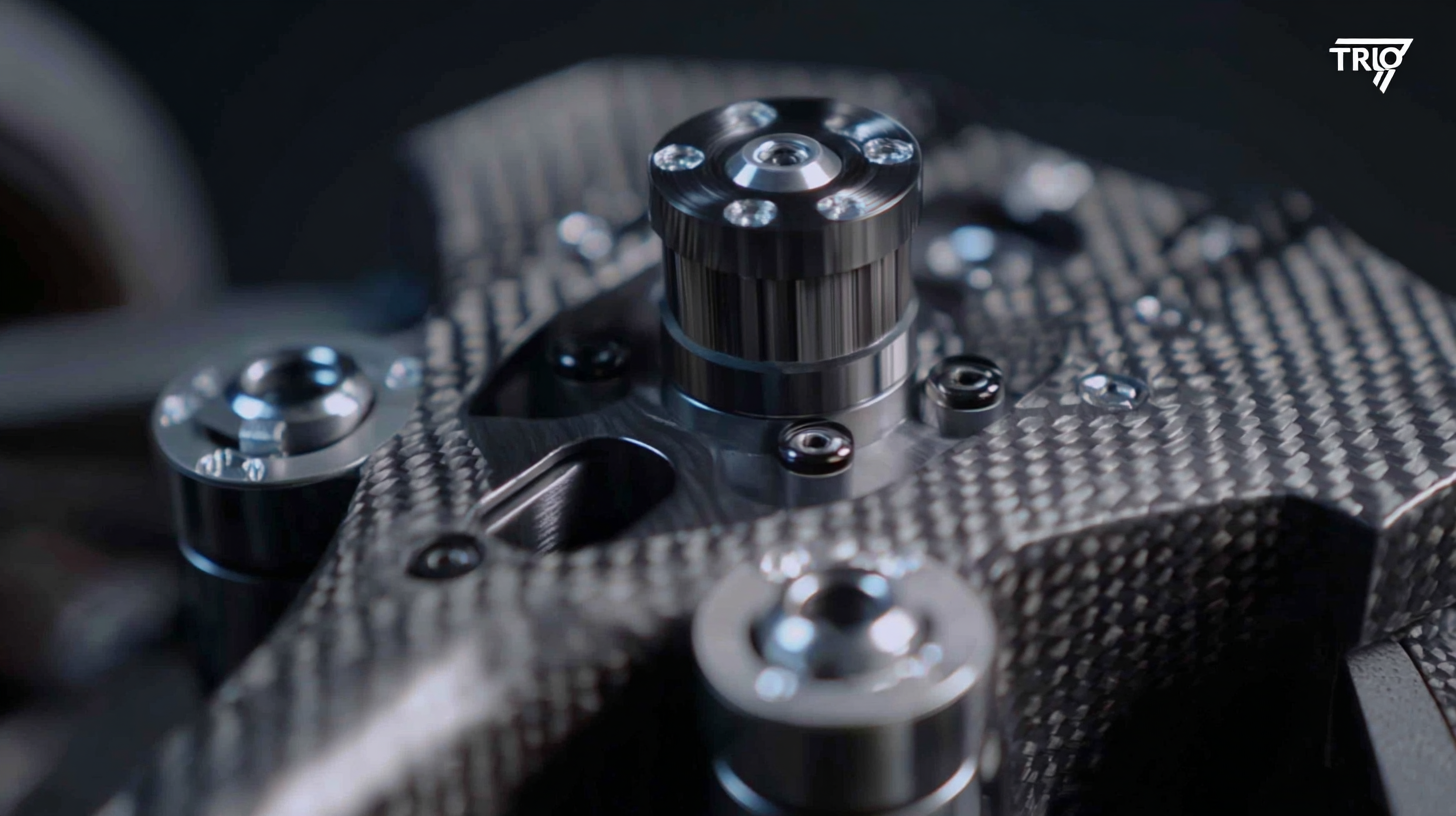

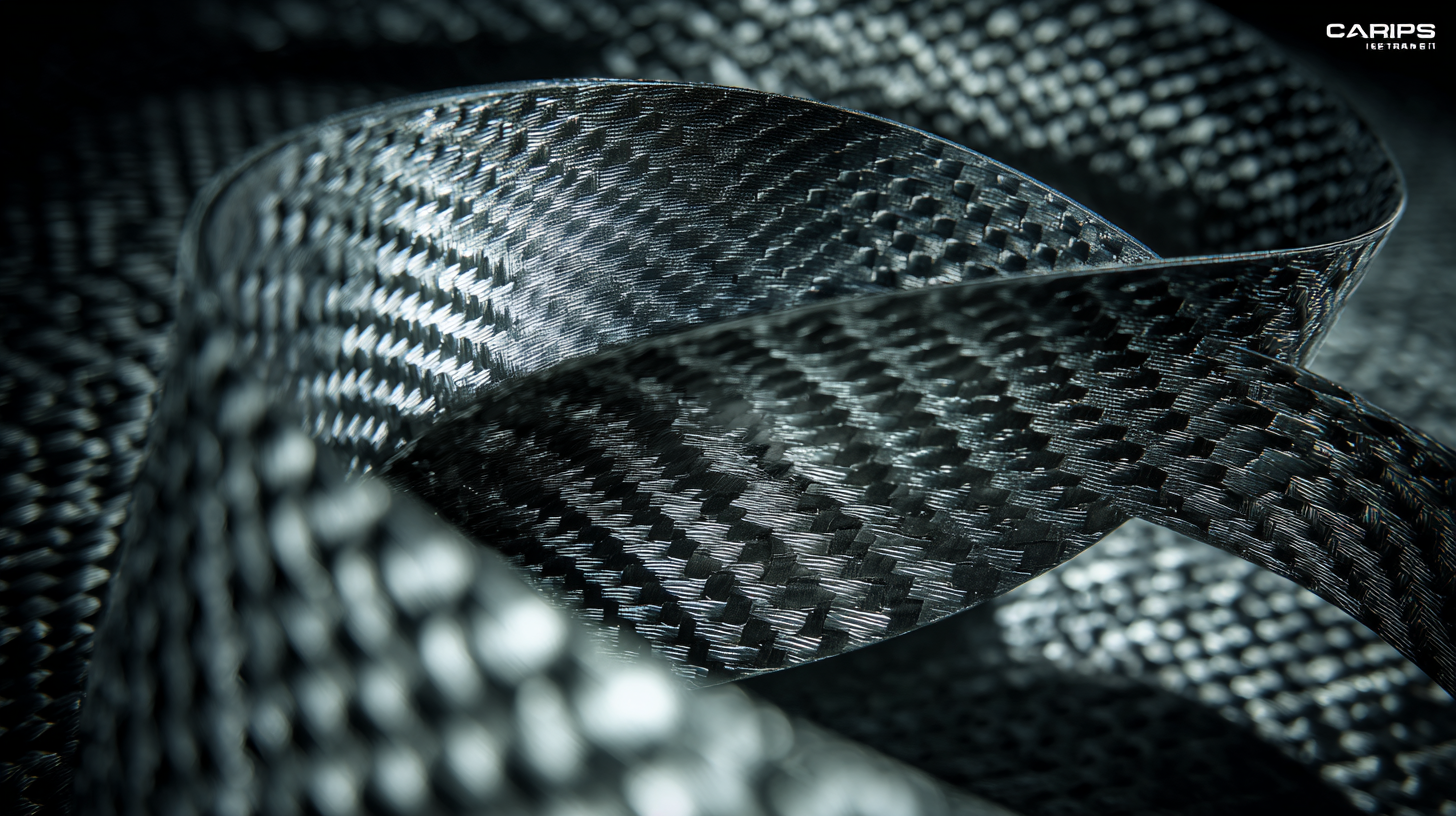

In recent years, Triopd Carbon Fiber has emerged as a revolutionary material reshaping industries like aerospace and photography. Known for its lightweight, yet robust characteristics, Triopd Carbon Fiber offers a unique blend of durability and performance that meets the stringent demands of modern engineering and artistry.

In the aerospace sector, it contributes to significant weight savings in aircraft design, enhancing fuel efficiency and payload capacity. Meanwhile, in photography, its remarkable strength-to-weight ratio enables the creation of high-quality tripods and camera supports, allowing photographers to achieve stability without the bulk.

As the demand for superior materials continues to rise, understanding how to choose a quality manufacturer of Triopd Carbon Fiber is crucial for both industries. This blog will delve into the applications of this innovative material and guide readers on selecting the best manufacturers to ensure they meet their project requirements with excellence.

The aerospace industry has seen remarkable advancements thanks to the use of Best Triopd Carbon Fiber. Its lightweight yet strong properties make it an ideal material for aircraft structures, components, and even satellites. This innovative material helps reduce fuel consumption and increase the overall efficiency of aerospace vehicles. Utilizing Best Triopd Carbon Fiber allows engineers to design more aerodynamic shapes without compromising structural integrity, paving the way for the next generation of aircraft that can sustain high speeds and altitudes.

When working with Best Triopd Carbon Fiber, it’s important to remember a few tips. First, ensure that your manufacturing processes are well-optimized to handle the specific characteristics of carbon fiber, as improper techniques can result in weak spots or inconsistencies. Second, always conduct thorough testing of carbon fiber components to guarantee their performance under varying stresses and conditions. Lastly, consider integrating these components early in the design phase to fully leverage their benefits in terms of weight reduction and strength enhancement.

In addition to its aerospace applications, Best Triopd Carbon Fiber has found a place in the photography industry, especially in tripods and camera rigs. Its lightweight nature allows photographers to carry their gear easily while ensuring stability and durability. Designers should pay attention to the ergonomic aspects when creating products with carbon fiber to enhance user experience.

The aerospace industry is continuously seeking innovative materials to enhance efficiency and performance, with carbon fiber emerging as a leading option due to its exceptional strength-to-weight ratio. According to a report by Technavio, the global market for carbon fiber composites in aerospace is expected to grow by $1.14 billion from 2020 to 2024. This remarkable growth is primarily attributed to the material's ability to significantly reduce weight, which is crucial in an industry where every gram saved translates to improved fuel efficiency and extended range.

One of the most compelling advantages of using carbon fiber in aerospace applications is its potential for weight reduction. For instance, the Boeing 787 Dreamliner utilizes approximately 50% composite materials, largely carbon fiber reinforced polymers, which contributes to a weight reduction of around 20-30% compared to conventional aluminum designs. This reduction results in lower operational costs and increased payload capacity, making carbon fiber an attractive choice for manufacturers aiming to meet stringent environmental regulations while enhancing aircraft performance. As the demand for lightweight and fuel-efficient aircraft grows, the reliance on carbon fiber will undoubtedly continue to rise, revolutionizing the future of aviation.

The photography industry is experiencing a transformative shift with the integration of advanced carbon fiber technology. Known for its lightweight and durable properties, carbon fiber is increasingly being utilized in the production of camera supports, tripods, and other crucial equipment. According to a recent report from the Photographic Research Organization, the usage of carbon fiber components in photography gear has increased by 35% over the past five years, significantly enhancing both portability and stability for professional photographers.

One of the most noticeable advantages of carbon fiber in photography is its ability to absorb vibrations, resulting in sharper images, especially in long-exposure scenarios. This characteristic is particularly beneficial for landscape, astrophotography, and macro photography, where the slightest shake can ruin the shot. Photographers are encouraged to invest in gear that incorporates this technology to maximize image quality and ensure reliability during shoots.

Tips for Photographers:

In recent years, carbon fiber has garnered significant attention as an innovative material in both the aerospace and photography industries. One of the key advantages of carbon fiber compared to traditional materials like metals is its superior strength-to-weight ratio. This property not only allows for lighter designs but also enhances performance, particularly in aerospace applications where every gram counts. The design versatility of carbon fiber also outstrips that of metals, as it can be engineered to be anisotropic, allowing for tailored properties that meet specific requirements.

When considering repair costs, carbon fiber presents a compelling case. While initial manufacturing costs may be higher than those of traditional materials, the longevity and durability of carbon fiber often result in lower maintenance and repair expenses over time. For instance, in the automotive and high-speed train sectors, the lightweight and corrosion-resistant nature of carbon fiber contributes to significant energy savings and reduced wear, ultimately driving down operational costs. As industries continue to innovate and adopt carbon fiber technologies, understanding the comparative repair costs will be crucial in guiding investment decisions and designing sustainable solutions.

| Industry | Material Type | Repair Cost (per unit) | Weight (kg) | Durability (Years) |

|---|---|---|---|---|

| Aerospace | Carbon Fiber | $1,500 | 5.0 | 20 |

| Aerospace | Aluminum | $2,000 | 7.5 | 15 |

| Photography | Carbon Fiber | $300 | 1.2 | 10 |

| Photography | Plastic | $150 | 1.5 | 5 |

In the fast-evolving industries of aerospace and photography, the integration of best triopd carbon fiber products has transformed operational standards and performance benchmarks. A significant aspect often overlooked is the after-sales service that enhances the longevity and efficiency of these high-performance materials. According to a recent report by the Frost & Sullivan Group, the global carbon fiber market is projected to reach USD 6.3 billion by 2025, highlighting the crucial need for robust after-sales support to maintain customer satisfaction and operational excellence.

Effective after-sales service for carbon fiber products includes regular maintenance, prompt repairs, and access to technical support, which can significantly extend the product lifespan. The composite materials used in aerospace applications, where safety is paramount, require diligent monitoring and servicing. Notably, a report from the National Composite Center states that proper after-sales handling can increase the lifespan of carbon fiber components by over 30%. In photography, where precision is critical, after-sales services ensure that equipment remains in top shape, allowing for optimal performance during critical shoots. Providing excellent after-sales support not only builds brand loyalty but also drives repeat business in both the aerospace and photography sectors.